Introduction:

The manufacturing industry is facing considerable change, all due to technological innovations that enhance efficiency, accuracy, and creativity. From these technology advancements, industrial 3D scanning services have proven to be a game changer.

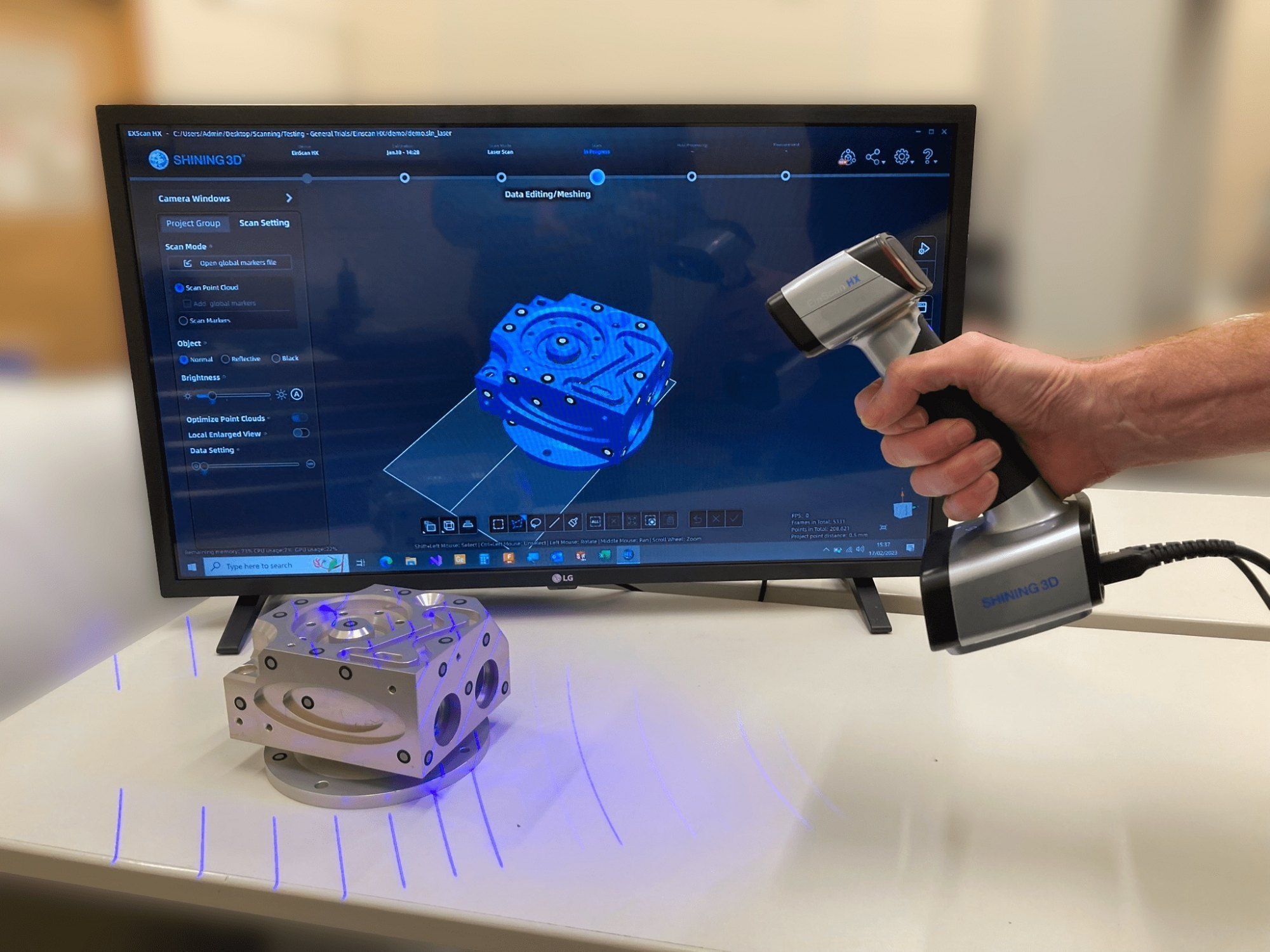

3D scanning has paved the way in manufacturing for a variety of uses, including design and prototyping and quality control and maintenance, by enabling the capturing of direct data about natural physical objects accurately with high dimensional resolution.

Below are details on industrial 3D scanning services that are transforming the manufacturing sector, including their advantages, applications, and immense changes.

Improving the Product Design and Prototyping

From product design to prototyping — industrial 3D scanning has enabled engineers to capture the geometry of existing components quickly and accurately or offer them completely new designs.

- Reverse engineering: If the original design files are not available, 3D scanning allows manufacturers to reverse engineer physical parts. Engineers are not only able to analyze scanned data but also pick necessary design elements and replicate or enhance the part.

- Iterative Design: The accelerated iterative design process through quick data acquisition from 3D scanning. Engineers then can alter prototypes, scan the new designs, and analyze them for performance gains in real time.

This allows for the reduction of product development cycle costs and, ultimately, better-performing products in a more precise manner within rapid time frames.

Enhancing Quality Control and Inspection

Quality control and inspection are among the most robust applications of 3D scanning in manufacturing. Conventional inspection processes like calipers and gauges are time-consuming, labour-intensive, and cannot measure complex geometries.

The faster, more correct answer that industrial 3D scanning services provide helps assure an entire picture of an object, consisting of its size, floor end, and structural integrity. By comparing this data with the original CAD design, deviations or defects can be detected.

It reduces waste, minimizes rework, and ensures final products conform to quality standards by detecting defects early in the production process.

Manufacturing process efficiency

Tool and Mold Inspection: 3D scanning helps to ensure molds, dies, and tooling elements are made according to exact specifications. This level of accuracy ensures tools take less time to produce because they are defective or mistitled.

Assembly validation: By scanning the assembled product, manufacturers can ensure that the components match and operate correctly. This is an essential step for preventing expensive assembly mistakes.

Speedy duplication: It is never easy to find spare parts or replacements where 3D scanning enables speedy replication, even if the original design files still need to be included.

These efficiencies allow manufacturers to cut production time costs and continue delivering high-quality products.

Supporting Maintenance and Repairs

For example, in aerospace, energy, and heavy machinery sectors, retaining equipment reliability is a top priority. 3D scanning technology is instrumental in maintenance and repair processes by quickly capturing 3D data of worn or broken parts.

Damage Assessment: With the use of scanned data, engineers can evaluate wear and corrosion or damage to structures with great precision. It provides this insight to decide if a component should be repaired or replaced.

Replacement of Parts: industrial 3D scanning services can recreate perfect replicas when replacement parts are not easy to procure, preventing delays in equipment operation.

This feature minimizes downtime and increases the lifespan of costly equipment, translating to substantial cost savings for businesses.

Driving Innovation with Digital Twins

The idea of a digital twin—virtual twins of natural objects or systems has become popular in manufacturing. This innovation happens at this junction through industrial 3d scanning services that link the real and digital worlds efficiently for accurate digital twin creation with footsteps in both worlds.

As a result, manufacturers can evaluate product performance in virtual environments before physical production, hence creating digital twins. It helps not just minimize the risks but also enables predictive maintenance, real-time monitoring, and, eventually, improving manufacturing workflows.

Facilitating Sustainability in Production

As such, manufacturers build more sustainable practices into their operations; 3D scanning helps with this in a number of ways:

Material Optimization: Scanned data allows manufacturers to find areas in which they can reduce material use without sacrificing product performance.

Waste Minimization: The design and production errors are minimized through accurate scanning, thus jolting down the wastage of material caused by defective parts or rework.

Lifecycle Management: Scanning provides manufacturers with the ability to trace and track components along their lifecycle, ultimately allowing for more efficient recycling and reuse.

All of these advantages come right on the heels of increasing demand for green manufacturing.

Applications Across Industries

3D scanning service has more versatile features that are implemented in various industries, such as:

Aerospace: Making certain parts are manufactured and maintained precisely.

Automotive: Making designs best and enhancing quality checks.

Healthcare: Custom prosthetics and other medical devices

Energy: Upgrading and maintaining essential infrastructure.

Consumer Goods, bringing acceleration to product development and individualization.

Conclusion

Industrial 3D scanning services offer a faster, more accurate, and practical concept to design, manufacture, and maintain products compared to the conventional manufacturing process. 3D scanning is a disruptive technology that keeps on enabling developments, from improving goods design and quality management to simplifying manufacturing workflows or assisting sustainability efforts.

Read More: Exploring the Benefits of 3D Building Scanning Services