Coated papers have revolutionized the packaging circle with custom greaseproof paper being very essential in food packaging. This type of paper is intended to be stain resistant to grease and moisture ideal for different purposes in kitchen adel, restaurants, and bakeries among others.

This paper helps one understand the process of production of this important material and get to know some of the effort that goes into ensuring a product with so many applications to businesses and corporate entities is crafted. Read on to learn more about the amazing process of custom greaseproof paper manufacturing.

The Raw Materials

The manufacture of custom greaseproof paper involves the identification of high-quality materials to be used in the production. The primary constituent is cellulose fibre, usually obtained from wooden pulp. The best of these fibres are selected to have the right ability to absorb and also the right strength. The cellulose is then refined into pulp, after which several additional treatments are given to the pulp to improve its grease-retentive properties. Such carefully chosen staples guarantee that the result complies with, and sometimes even surpasses, market and environmental expectations.

Transforming Pulp into Paper

Once the raw materials are ready the pulp passes through various processes to produce custom greaseproof paper. The product called pulp is mixed with water to engineer what is known as the slurry, which is then forwarded to the paper-making machine. Here, the water is removed, and the fibers also knit to the formation of papers or sheets or webs. The sheets are then rolled and baked to the required thickness for the texture of linen on the surface of the cloth. There’s always a high emphasis on this particular step of manufacturing grease-proof paper sheets so that the paper is very strong and can pull through every single day.

Applying The Grease-Resistant Coating

Following the manufacture of paper, they are then coated with what can best be referred to as a grease-resistant layer. That is where customizations come in handy because the manufacturers can opt for different formulations depending on the application of the paper. The coating is normally formed from natural or synthetic material to minimize the absorption of oil and moisture. This step is very important in designing a product that will finish greasy foods without any detriment to the product’s stability. The finality is thus a sensible greaseproof paper bag that holds contents well without wetting or staining them.

Customization

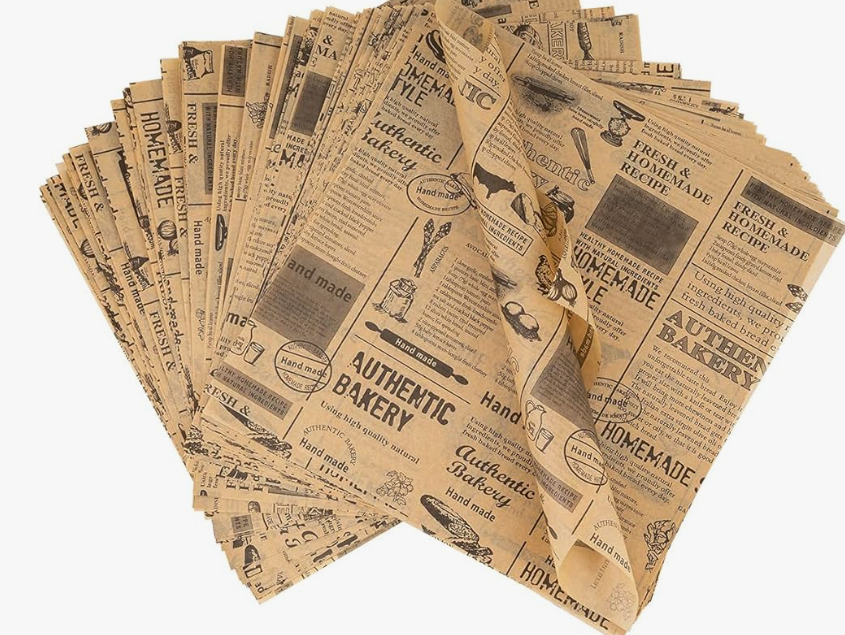

Marketing research today reveals that branding and customer’ customization are vital factors in competition. This is why many companies are considering Christmas custom-printed greaseproof paper. Following marketing when it comes to the actual production of the paper products, a business can opt to print logos, colours, and designs. The printing process commonly used in production is flexographic or digital printing to provide high-quality graphics that may not fade when exposed to grease and moisture. It does this not only to increase its visibility but also to support an aesthetic appeal for the food goods on display.

Maintaining Uniformity and Efficiency

It is especially important to pay attention to the quality control of greaseproof paper. Manufacturers employ testing protocols so that quality control on the printed greaseproof paper sheets is met each time there is production of new batches. Some of the usability test assessments could be checking the paper’s ability to repel grease, and water as well as checking the tearing strength of the paper. Further, the accuracy of the prints is checked to ensure that the designs produced are bright and very sharp. This commitment to quality helps to make sure businesses use a product that performs in check hence supporting their brands.

Distribution and Availability

Depending on the type of custom greaseproof paper, it is ready for distribution after the product is manufactured and goes through several checks to ensure quality delivery. There is greaseproof paper wholesale for sale from which many manufacturers and sellers offer their products at lower prices in bulk. This is especially advantageous to restaurants, café and companies offering catering services as they have to purchase packaging products in bulk. Through offering wholesalers, manufacturers give an assurance and simplify a business’s supply chain by reducing the need for constant restocking all while doing so at a cheaper price than buying the products in smaller lots.

Pizza box liners are essential for maintaining the freshness and quality of pizza during transport. They act as a barrier, preventing grease and moisture from seeping into the box, ensuring a clean presentation and an enjoyable eating experience. Custom pizza liners can also enhance branding and customer satisfaction.

Conclusion

The creation of greaseproof paper with clients’ specifications is a complicated one, which involves scientists, artists, and technologists. Starting from the acquisition of the raw material to the usage of distinctive design in the product all the aspects are essential in producing a product that will suit the needs of the food industry. Ensuring that businesses have the best packaging solution is therefore the reason that manufacturers put their best foot forward to develop new ways of making custom greaseproof paper. Therefore the need to unravel the processes that lead to the creation of sustainable and efficient packaging as the market demand for them extends. Thanks for visiting!