In the manufacturing of electrical cable connectors, selecting the right material is essential for ensuring reliability, durability, and high performance, especially under extreme conditions. Traditional materials like copper and aluminum have been widely used for decades. However, with evolving technology and the increasing demand for high-performance materials, industries now prefer superalloys like Inconel as the go-to option. Inconel 925 bars manufacturers are at the forefront of this revolution, providing a solution that overcomes the limitations of conventional materials. This blog explores why Inconel 925 bars are emerging as a superior choice for electrical cable connectors, offering distinct advantages over traditional materials.

What is Inconel and Why Is It Ideal for Electrical Cable Connectors?

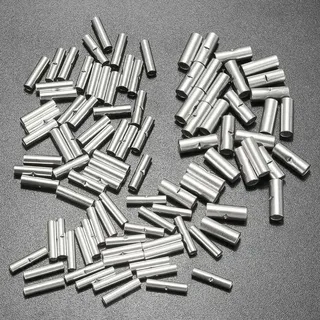

Inconel 925 is a specific grade of Inconel known for its superior performance in high-stress applications. Inconel 925 combines nickel, chromium, copper, and molybdenum for excellent corrosion resistance and high-temperature durability. These traits make it a reliable and long-lasting choice for electrical cable connectors, surpassing traditional materials like copper and aluminium.

Benefits of Inconel Bars in Electrical Cable Connectors

- Corrosion Resistance

One of the most notable advantages of Inconel bars, especially Inconel 925, is their exceptional resistance to corrosion. In environments with moisture, saltwater, or corrosive materials, copper and aluminium degrade over time, reducing performance. In contrast, Inconel 925 bars resist corrosion, ensuring longer-lasting, low-maintenance connectors. This makes them an excellent choice for industrial, marine, and aerospace applications, where connectors are exposed to harsh environments.

- High-Temperature Stability

Electrical cable connectors are often exposed to extreme temperatures, particularly in industrial and automotive settings. Copper and aluminium lose strength and conductivity at high temperatures, while Inconel 925 bars maintain integrity and performance, making them ideal for electrical connectors in hot environments.

- Durability and Tensile Strength

Inconel 925 bars provide remarkable mechanical properties, including high tensile strength and durability. Electrical cable connectors often face mechanical stresses, particularly in industrial and automotive applications. The tough nature of Inconel 925 makes it resistant to deformation under high mechanical loads, ensuring that connectors do not fail prematurely. This durability is a key advantage of using Inconel 925 bars, as they can withstand the stresses that would cause traditional materials to degrade or break.

- Good Electrical Conductivity

Although copper has better conductivity, Inconel alloys excel where high resistance and durability are key.

-

Why Inconel 925 Bars Should Be Used for Electrical Cable Connectors

- Improved Material Properties

Inconel 925 bars are known for their exceptional resistance to oxidation, acids, and high-temperature conditions. Inconel 925’s superior mechanical properties make it perfect for electrical cable connectors in harsh conditions. It outperforms traditional materials in longevity and reliability, making it the top choice for aerospace, automotive, and power generation industries.

- Resilience in Extreme Conditions

Inconel alloys, particularly Inconel 925, are designed to withstand the most demanding environments. Aerospace, marine, and petrochemical industries rely on Inconel for its ability to resist extreme pressure and hostile conditions. Similarly, electrical cable connectors used in these industries benefit from the unmatched resilience of Inconel 925 bars. The ability of these bars to endure high temperatures, pressure, and corrosive environments makes them the ideal choice for cable connectors in industries with demanding performance requirements.

- Cost-Effectiveness Over Time

Although Inconel 925 bars may have a higher upfront cost compared to traditional materials such as copper or aluminium, the long-term benefits make them more cost-effective. Inconel 925 connectors require less maintenance and have a longer operational life, which reduces the need for frequent replacements or repairs. This translates into lower overall operating costs and fewer downtime incidents. As a result, the durability and reliability of Inconel 925 bars make them a more economical choice in the long run.

- Optimized for Challenging Applications

In industries where connectors face severe environmental conditions, materials that are highly durable and reliable are critical. Inconel 925 bars excel in these scenarios by providing superior performance under high-stress, high-temperature, and corrosive environments. Electrical cable connectors made from Inconel 925 bars can withstand the demands of challenging applications, ensuring that they continue to perform reliably throughout their lifespan.

Conclusion

Inconel 925 bars offer numerous advantages over traditional materials like copper and aluminium in the manufacturing of electrical cable connectors.

For electrical cable connector applications, partnering with an Inconel 925 bars manufacturer ensures that you are using the best materials available.

Inconel 925 bars exceed performance requirements for electrical connectors in extreme conditions, offering unmatched reliability and longevity. For optimal performance and durability, choose Inconel 925 bars.

Incorporating Inconel 925 bars ensures your connectors perform reliably in tough environments for years.