Diesel trucks are engineered for power, endurance, and efficiency, but over time, the fuel system in your diesel truck can wear down or experience issues that may compromise its performance. Identifying the signs of fuel system failure early is crucial for maintaining your truck’s longevity and avoiding costly repairs. In this article, we will walk you through how to tell if your diesel truck needs fuel system repair and what steps you should take if you encounter any of these symptoms.

Understanding the Diesel Fuel System

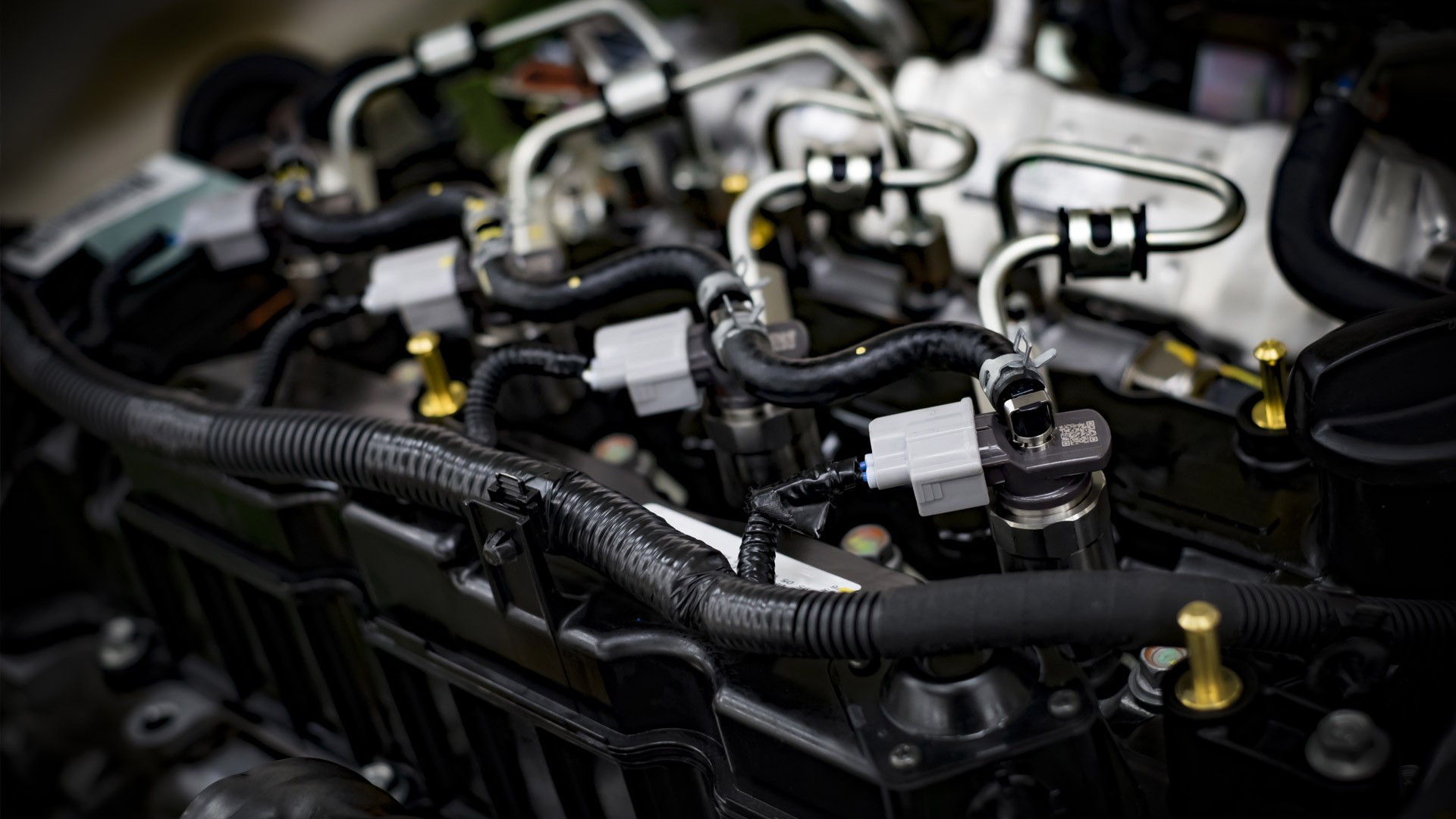

Before delving into the warning signs of fuel system issues, it’s important to understand how the diesel fuel system operates. In diesel engines, the fuel system is responsible for delivering the precise amount of fuel to the engine’s combustion chamber at the right time and pressure. The system includes the fuel tank, fuel pump, injectors, and fuel filters. Over time, these components can wear out, become clogged, or malfunction, leading to a decrease in performance, fuel economy, or worse, complete engine failure.

Common Symptoms of Diesel Truck Fuel System Problems

1. Difficulty Starting the Engine

One of the most noticeable signs that your diesel truck may need fuel system repair is difficulty starting the engine. If your truck takes multiple tries to start or doesn’t start at all, it could indicate issues within the fuel system. Common causes include:

- Clogged fuel filters: Fuel filters are designed to keep debris and contaminants from entering the fuel system, but if they become clogged, it can restrict fuel flow, making it difficult for your engine to start.

- Failing fuel pump: The fuel pump delivers fuel from the tank to the engine. If the pump fails, the engine won’t receive enough fuel to start.

- Air in the fuel lines: Air bubbles can prevent fuel from reaching the combustion chamber, causing hard starts.

2. Loss of Power and Poor Performance

Another red flag that your diesel truck’s fuel system needs repair is a loss of power, especially under load. If your truck struggles to accelerate or maintain speed, it may not be getting enough fuel. This can be due to:

- Fuel injector problems: Faulty or clogged fuel injectors can lead to poor atomization of fuel, resulting in insufficient combustion and power loss.

- Low fuel pressure: The fuel system requires a specific amount of pressure to operate efficiently. If the pressure drops due to a failing fuel pump or leak in the fuel lines, it can cause a noticeable decrease in performance.

3. Decreased Fuel Efficiency

Diesel trucks are known for their fuel efficiency, but if you notice a sudden drop in miles per gallon (MPG), it could be a sign of a fuel system issue. Causes of reduced fuel efficiency include:

- Leaking fuel lines: Fuel leaks reduce the amount of fuel that reaches the engine, forcing it to work harder to maintain performance, which in turn consumes more fuel.

- Clogged injectors: When fuel injectors become clogged, they don’t deliver the proper amount of fuel, leading to incomplete combustion and wasted fuel.

- Malfunctioning fuel sensors: Inaccurate fuel readings can lead to the engine receiving too much or too little fuel, negatively impacting fuel efficiency.

4. Excessive Smoke from the Exhaust

While some exhaust smoke is normal in diesel engines, excessive or unusual smoke is a strong indicator that something is wrong with your fuel system. The color of the smoke can provide clues about the underlying issue:

- Black smoke: Black smoke is usually a sign of too much fuel being burned. This can happen if the fuel injectors are stuck open or leaking, or if the air-to-fuel ratio is unbalanced.

- White smoke: White smoke typically means that the fuel is not burning properly, which could be caused by clogged injectors, low fuel pressure, or even water in the fuel.

- Blue smoke: Blue smoke often indicates that oil is mixing with the fuel, which could be a sign of internal engine problems that require immediate attention.

5. Engine Misfires and Rough Idling

If your diesel truck is idling roughly or experiencing engine misfires, it could be a symptom of fuel system trouble. Misfires and rough idling often occur when the fuel injectors aren’t delivering the right amount of fuel or when air has entered the fuel system. This can lead to uneven combustion, causing your engine to run erratically.

6. Unusual Noises from the Fuel Pump

The fuel pump in your diesel truck should operate quietly in the background. However, if you hear unusual noises like whining, buzzing, or clicking from the fuel tank area, it could mean that your fuel pump is struggling to deliver fuel to the engine. This may be a sign that the pump is nearing failure and should be inspected or replaced as soon as possible.

7. Check Engine Light or Warning Lights

Modern diesel trucks are equipped with sophisticated diagnostics systems that can alert you to potential problems within the fuel system. If your check engine light comes on, it could be due to a fuel system issue such as:

- Faulty fuel injectors

- Low fuel pressure

- Problems with the fuel pump

While the check engine light could be triggered by a wide range of issues, it’s always important to have your truck diagnosed by a professional mechanic to determine if the fuel system is the culprit.

What Causes Diesel Fuel System Problems?

There are several factors that can lead to fuel system issues in diesel trucks, including:

- Contaminated fuel: Diesel fuel can sometimes contain impurities like dirt, water, or algae, which can clog injectors, filters, and lines, leading to poor performance or failure.

- Wear and tear: Like any mechanical system, the fuel system components degrade over time due to regular use, especially if maintenance is neglected.

- Poor maintenance: Failing to regularly replace fuel filters, inspect fuel lines, and clean injectors can accelerate the wear of your fuel system.

How to Prevent Fuel System Failures

Preventing fuel system issues involves routine maintenance and being attentive to the performance of your truck. To ensure the longevity and efficiency of your fuel system:

- Replace fuel filters: Change your fuel filters as recommended by your truck’s manufacturer to prevent clogs.

- Use high-quality fuel: Make sure you’re using high-quality diesel fuel to avoid contamination.

- Clean injectors regularly: Diesel fuel injectors can accumulate deposits over time, so regular cleaning can help maintain proper fuel delivery.

- Inspect fuel lines: Regularly check your fuel lines for leaks or damage, and replace any faulty lines to prevent pressure loss or fuel waste.

Conclusion

The fuel system in your diesel truck plays a critical role in ensuring optimal performance, fuel efficiency, and longevity. By being aware of the warning signs—such as hard starts, power loss, decreased fuel efficiency, and unusual smoke—you can detect potential fuel system problems early and seek professional repairs before they escalate. Routine maintenance and proactive inspections are key to preventing fuel system failures and keeping your diesel truck running smoothly for years to come.