Cable management in today’s industrial settings is not so much a question of tidiness, but a question of health and productivity and success. Finally, it is possible to note one of the most efficient systems of supplying electrical wiring in industrial conditions – the Cable Tray system. For many years, a well-engineered communication cable tray system has been considered a foundation for safe and efficient operation at Western Control.

What Are Cable tray?

A Cable Tray is a structural member, design to accommodate electrical cables in industrial and commercial establishments. It offers a safe route for the wiring, flexibility, consideration as well as mechanical reliability. They are of different material types, such as steel, aluminum and fiberglass depending on the industrial needs that they are needed for.

Due to their ability to suspend cables off the ground and away from areas of danger, Cable tray always come with a lot of benefits despite eliminating certain features.

Enhancing Safety in Industrial Settings

Electricity is one of the primary dangers in industrial businesses as protecting lives comes first and so as the machinery. Here are several ways Cable tray contribute to a safer environment:

1. Minimizing Trip Hazards

Loose wires and cables strewn across floors are a common cause of workplace accidents, such as trips and falls. Installing a Cable Tray eliminates this issue by keeping cables elevated and organized. This not only protects employees but also complies with workplace safety regulations.

2. Fire Risk Reduction

Electrical fires can result from overheating cables, poor insulation, or short circuits. Cable tray made from fire-resistant materials help contain wiring and prevent excessive heat buildup. Additionally, the open design of many cable tray systems facilitates airflow, further reducing the risk of overheating and potential fire hazards.

3. Improved Emergency Response

In the event of an emergency, a well-organized cable management system ensures that critical power and communication lines are easily identifiable. This allows for quicker troubleshooting and safer maintenance procedures, minimizing downtime and enhancing safety protocols.

4. Protection from Physical Damage

Cables running along floors or walls are vulnerable to physical damage from machinery, vehicles, or foot traffic. Cable Tray provide a sturdy barrier, safeguarding the integrity of the wiring and reducing the risk of electrical faults or interruptions.

Boosting Efficiency with Cable tray

In addition to enhancing safety, Cable tray play a vital role in improving operational efficiency. Let’s explore how they streamline industrial processes:

1. Simplified Installation and Maintenance

Compared to conduit system , cable tray system is relatively easier to install. The five buildings can now be modified or extended more quickly and at a lower cost than if they were one monolithic structure. The cables can also be easily checked by technicians without the need to dismantle the system, hence the maintenance of the system is very easy.

2. Optimized Space Utilization

Space is a critical input in factors of production and Cable Tray help to utilize this input in industrial facilities effectively. Suspended by a wide range of mounting methods including by cable carriages along walls and ceiling, Cable tray allow for efficient utilization of floor space for movements made necessary by machinery, storage among other functions.

3. Enhanced Scalability

There are always changes in industries as activities occur Over the years industries have grown through expansion and new equipment and electrical systems may be needed. They can flexibly be modified in terms of space to meet the required changes in the future without a lot of fuss. This scalability makes it possible to achieve long-term cost-effectiveness besides flexibility in operations.

4. Improved Workflow Efficiency

Selecting the right Cable Tray is essential for achieving optimal safety and efficiency. Here are some common types and their applications:

- Ladder Cable tray: Ideal for supporting heavy cables over long spans. Their open design allows for excellent heat dissipation.

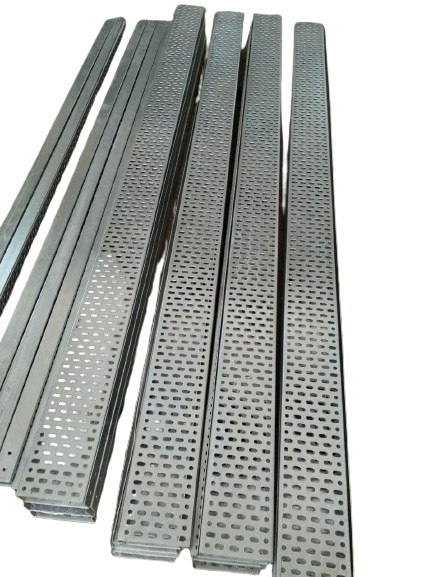

- Perforated Cable tray: Suitable for light to medium-weight cables. The perforations offer ventilation and easy customization.

- Solid Bottom Conduit Tray : Best for sensitive cables that require complete protection from external elements, such as dust and moisture.

- Wire Mesh Cable tray: Perfect for environments requiring flexibility and quick installation. Often used in data centers and light industrial setups.

At Western Control, we offer a variety of cable tray solutions to meet the specific needs of your industrial environment.

Key Benefits of Cable tray in Industrial Settings

- Durability: Electrical Tray are made from robust materials that can withstand harsh conditions, including high temperatures, chemical exposure, and heavy loads.

- Cost-Effectiveness: By reducing installation time, maintenance effort, and cable damage, Cable tray offer significant cost savings over their lifespan.

- Regulatory Compliance: Proper cable management helps industrial facilities meet safety standards and avoid penalties.

- Aesthetic Appeal: An organized Cable Raceway system creates a cleaner and more professional-looking workspace, which is particularly important for facilities that host client visits or audits.

Why Choose Western Control for Your Cable Tray Needs?

Currently, Western Control specializes in providing excellent cables management solutions for industrial purposes. The Wire Tray system is produced with accuracy and measured so that it meets safe and long lasting standards as well as easily assembled. Regardless of whether you require a unique bespoke bespoke solution or an off the shelf design, our team can help you optimise business in the industrial sector.

Conclusion

While in the industrial complex the two vital aspects of process aare safety and efficiency. Such a cable tray design takes both these considerations into account and provides a secure means of accommodating electrical wiring. Cable Tray are therefore instrumental in following aspects such that it minimizes potential dangers, easy in terms of installation and servicing, as well as space saver in most industries.

If you’re looking for an efficient cable management system tailored to your needs, visit Western Control. Call or email us today to discuss how we can fully equip your industrial space with our Cable tray.