In the ever-evolving world of industrial applications, the integration of advanced technologies has led to transformative changes in how businesses operate. One such revolutionary concept is the implementation of digital twins, which have gained traction for their ability to simulate, analyze, and optimize real-world processes in a virtual environment. This innovation holds significant potential for enhancing UI/UX design services tailored to industrial needs. By leveraging digital twins, companies can create intuitive, efficient, and interactive user interfaces that allow users to visualize and interact with data-driven systems in real-time. This article delves into the role of digital twins in UI/UX design services for industrial applications and how software development companies can harness this technology to drive innovation and improve user experiences.

What Are Digital Twins?

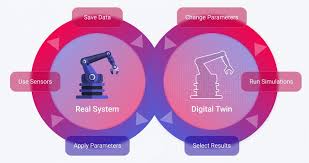

A digital twin is a virtual representation of a physical object, system, or process. It allows for the simulation of real-world conditions in a digital space, enabling industries to monitor, analyze, and optimize operations with precision. Digital twins combine data from sensors, IoT devices, and machine learning algorithms to replicate real-time behavior, making them invaluable for industries such as manufacturing, construction, and energy.

In UI/UX design services, digital twins serve as a bridge between physical operations and the virtual world. They provide a real-time visualization of complex systems, which can enhance user interfaces by offering an interactive experience. By using UI/UX design services to create intuitive, visually appealing, and responsive interfaces for digital twins, businesses can improve user engagement, streamline workflows, and make data-driven decisions more accessible.

The Growing Importance of Digital Twins in Industrial Applications

Industries are increasingly adopting digital twin technology to improve operational efficiency, reduce downtime, and enhance product design and development. The integration of digital twins with UI/UX design services is critical in creating systems that are easy to interact with and provide actionable insights to users.

1. Enhanced Visualization and Data Representation

One of the most significant advantages of digital twins is their ability to visualize complex data. In industrial environments, users often need to monitor multiple systems or machinery at once. Digital twins, when paired with UI/UX design services, offer a platform where users can view real-time data in a clear, comprehensible manner. These visualizations include dynamic dashboards, 3D models, and real-time simulations that help users interact with data more effectively.

For instance, in manufacturing, digital twins can simulate factory floor operations, allowing users to visualize machine status, production rates, and potential bottlenecks. By designing engaging and easy-to-navigate interfaces, software development companies can ensure that users can access this information without being overwhelmed by data overload.

2. Real-Time Monitoring and Predictive Maintenance

Digital twins allow for the real-time monitoring of assets and systems, which is crucial in industrial environments where downtime can be costly. UI/UX design services play a key role in providing intuitive dashboards and control panels that present this data in a user-friendly format. By incorporating predictive analytics into these interfaces, industrial workers can receive real-time alerts for maintenance needs, reducing the likelihood of equipment failure.

For example, in the oil and gas industry, digital twins can simulate the performance of pumps, valves, and pipelines. Using UI/UX design services, a software development company can create an interface that not only visualizes the health of these assets but also predicts future failures based on historical data and trends. This proactive approach helps companies avoid costly disruptions while ensuring continuous operations.

3. Improved User Engagement Through Interactive Simulations

Digital twins provide an immersive, interactive experience that can enhance user engagement. By integrating UI/UX design services into digital twin platforms, users can interact with 3D models, manipulate variables, and simulate different scenarios to gain deeper insights into their systems.

For example, in the automotive industry, digital twins of vehicle components allow designers to interact with the parts virtually, testing their functionality and making improvements before physical prototypes are created. The UI/UX design services in such applications need to prioritize interactivity and usability, ensuring that users can easily navigate complex simulations and gain meaningful insights with minimal learning curves.

4. Customization for Different User Needs

Every industrial application has different user requirements. Digital twins, when combined with tailored UI/UX design services, allow for personalized user experiences. Different roles within an organization may require different levels of access to information. For instance, a plant manager may need high-level data on overall system performance, while a technician may need granular details about individual machines. By designing flexible interfaces, software development companies can ensure that digital twins are accessible and relevant to all users.

This level of customization is essential in industrial applications, where multiple users interact with the system on a daily basis. With the help of UI/UX design services, interfaces can be customized based on user roles, providing the right amount of detail and ensuring users are not overwhelmed by unnecessary information.

The Role of UI/UX Design Services in Maximizing the Potential of Digital Twins

While digital twins provide valuable insights and real-time data, their true potential can only be realized when paired with well-designed user interfaces. UI/UX design services play a critical role in making digital twins more accessible, engaging, and actionable. The success of digital twins in industrial applications depends largely on the quality of the interface through which users interact with the data.

1. Designing Intuitive Dashboards and Interfaces

One of the core aspects of UI/UX design services in digital twin applications is the creation of intuitive dashboards. These dashboards allow users to view and interpret complex data in a user-friendly manner. Effective design should prioritize clarity, with easy-to-read graphs, charts, and metrics that highlight key performance indicators (KPIs). Additionally, it should provide options for users to drill down into specific areas for more detailed analysis.

Software development companies can work with UI/UX design services to ensure that dashboards are not only visually appealing but also functional. For example, in a factory setting, a dashboard may show an overall performance overview, with interactive elements that allow the user to explore specific machines or production lines in more detail.

2. Ensuring Responsiveness and Flexibility

In the industrial sector, users may need to access digital twins from a variety of devices, whether on desktop computers, mobile devices, or augmented reality (AR) headsets. UI/UX design services must ensure that the interface is responsive across all devices, providing users with seamless experiences regardless of the platform.

For instance, plant managers may want to view the performance of their assets from a tablet while walking through the factory, while engineers might need to interact with the system through AR glasses to examine machines in the field. This flexibility in design ensures that digital twins remain functional and valuable across different contexts and environments.

3. Improving Data Interactivity and Decision-Making

Incorporating interactive elements into the design of digital twins is essential for enhancing user decision-making. UI/UX design services can enable users to manipulate variables in real-time, allowing them to test different scenarios and predict outcomes. This interactivity can improve decision-making by providing users with the tools to experiment with potential changes before implementing them in the physical world.

For example, in a power plant, operators may use a digital twin of the grid to simulate different energy demands and see how their system would respond under various conditions. The design must allow users to easily manipulate and interact with the virtual model to visualize potential outcomes and make informed decisions.

How Software Development Companies Leverage Digital Twins in UI/UX Design Services

Software development companies that specialize in industrial applications are increasingly adopting digital twin technology to offer comprehensive solutions to their clients. By integrating UI/UX design services into the development process, these companies can create platforms that not only deliver real-time insights but also provide an intuitive, engaging experience for users.

For example, a software development company might collaborate with industrial firms to create a digital twin of an entire manufacturing process. The company would then integrate UI/UX design services to ensure that the resulting platform is easy to use and capable of delivering the necessary insights to different types of users. This collaborative approach ensures that digital twin platforms are not just functional but also user-friendly, enabling companies to maximize their value.

Conclusion

Digital twins are revolutionizing the industrial sector, offering real-time insights, predictive maintenance, and enhanced decision-making capabilities. However, their true potential is unlocked only when paired with effective UI/UX design services. By creating intuitive, engaging, and responsive interfaces, software development company can ensure that digital twins are accessible and valuable to all users, from managers to technicians. As industries continue to adopt digital twins, the role of UI/UX design services will become even more critical in shaping the future of industrial applications. With thoughtful design and innovative technology, digital twins have the power to transform the way industries operate, creating more efficient and optimized workflows across the board.