Introduction

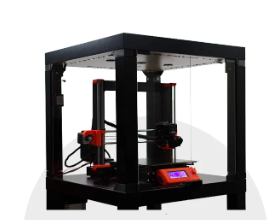

If you’re serious about enhancing the quality of your 3D prints while ensuring a safer workspace, adding a protective structure to your 3D printing setup is a game changer. Whether you’re working with ABS, PLA, or other materials, these structures help you maintain an optimal environment for better results and a smoother printing process.

Understanding the Concept of a Protective Shell for 3D Printing

Advantages of Using Protective Structures for Your Printer

Improving Print Outcomes

Using a protective covering ensures that your prints are more consistent and reliable by maintaining a stable environment. This is particularly important when using heat-sensitive materials like ABS that require a controlled temperature.

Regulating Temperature and Airflow

A protective structure helps regulate airflow and temperature, minimizing the risks of cooling too quickly or exposure to external drafts that could affect the print quality.

Types of Protective Solutions for 3D Printers

DIY versus Pre-assembled Options

DIY options allow you to customize your protective shell according to your printer’s specific needs. However, pre-assembled solutions are often more convenient and come with features like ventilation systems and temperature control.

Common Materials Used for Protection

Protective shells can be made from various materials, including acrylic for its lightweight and transparent qualities, wood for insulation, or metal for a more robust setup.

How a Protective Structure Improves Print Results

Ensuring Consistent Temperatures

A stable printing environment prevents temperature fluctuations that could lead to common issues like layer separation or uneven finishes, especially with materials like ABS or PETG.

Preventing Warping and Cracking

Warping and cracking often occur when materials cool too quickly or unevenly. By maintaining a warm, consistent environment, a protective structure reduces the likelihood of these problems.

Safety and Health Benefits

Minimizing Fumes and Noise

Some 3D printing filaments emit fumes during the printing process. A protective shell can help contain these fumes, making it easier to ventilate the workspace. Additionally, the shell acts as a sound barrier, reducing the noise level during operation.

Safeguarding Against High Temperatures

Since 3D printers can get quite hot, especially the build plate, a protective structure adds an extra layer of safety, keeping the hot components away from accidental contact.

Noise Reduction: A Quieter Printing Environment

One of the key benefits of a protective shell is noise reduction. 3D printers can be loud, especially in quiet environments like home offices. By containing the sound, these structures allow for a more peaceful workspace, whether you’re working or relaxing nearby.

Managing Environmental Factors

Shielding from Dust and Debris

Dust and debris can interfere with the 3D printing process by affecting the build surface or clogging printer parts. A protective shell keeps these contaminants at bay, ensuring a cleaner print environment.

Effective Heat Management

Retaining Warmth

The ability to trap heat inside the protective structure is crucial when working with materials like ABS, which require higher temperatures to print effectively. This retained heat helps to improve layer adhesion and overall print quality.

Suitability for Different Filament Types

While ABS benefits the most from controlled heat, even PLA, which is less temperature-sensitive, can see improved print quality when external conditions are regulated by a protective structure.

Best Practices for Setting Up a Protective Structure

Ventilation Tips

Though the protective shell is designed to retain heat, it’s essential to ensure proper ventilation, particularly if you’re using materials that release fumes. Installing fans or exhaust systems can help circulate air without compromising temperature control.

Installation Precautions

Ensure that your protective structure doesn’t obstruct the printer’s moving parts. Leave enough room for the printer to function freely, and avoid using flammable materials near high-heat components.

Building Your Own Protective Shell: DIY Guide

Step-by-Step Instructions

- Measure your printer: Make sure your protective shell will comfortably fit around your machine.

- Select materials: Acrylic, wood, or even repurposed furniture can serve as an effective protective covering.

- Assemble the frame: Construct a sturdy frame that allows for proper airflow and space for the printer to operate.

- Add finishing touches: Consider adding vents, windows, or access doors for easier maintenance.

Pre-built Solutions: Are They Worth the Investment?

Cost versus Convenience

While DIY options are often more affordable, pre-built protective structures save you the time and hassle of creating your own. They also come with additional features like integrated lighting, temperature control, and soundproofing.

Top Pre-made Solutions in the Market

- Creality Protective Shell: A cost-effective and user-friendly option for home 3D printers.

- Prusa Protective Cover: Designed for high-temperature printing materials, ideal for professional users.

- Delack Protective Enclosure: A premium solution with advanced insulation and noise-reduction capabilities.

Maintaining Your Protective Setup

Just like your printer, the protective shell requires regular cleaning and maintenance. Dust the interior frequently and check that any ventilation systems are functioning correctly to avoid overheating or blockages.

Conclusion

Adding a protective shell to your 3D printing setup is a smart investment, especially if you’re working with heat-sensitive materials or want to improve the consistency of your prints. Whether you choose to build your own or invest in a pre-made solution, these structures offer benefits ranging from better print quality to a safer and quieter work environment.

For more information click here

and read this