The global microchannel heat exchanger market size is expected to achieve USD 56.81 billion by 2032, growing at a CAGR of 13.2% between 2024 and 2032. The microchannel heat exchanger market is being driven by the growing automotive industry due to an increase in automotive manufacturing globally. These heat exchangers play a pivotal role in enhancing the efficiency of thermal management systems across various industries, particularly in automotive, HVAC, and commercial refrigeration applications. As industries strive for energy-efficient solutions and improved performance, the adoption of microchannel heat exchangers is expected to surge in the coming years.

In this blog post, we will delve into the key drivers, market segmentation, regional dynamics, competitive landscape, and emerging trends shaping the microchannel heat exchanger market from 2024 to 2032.

Market Overview

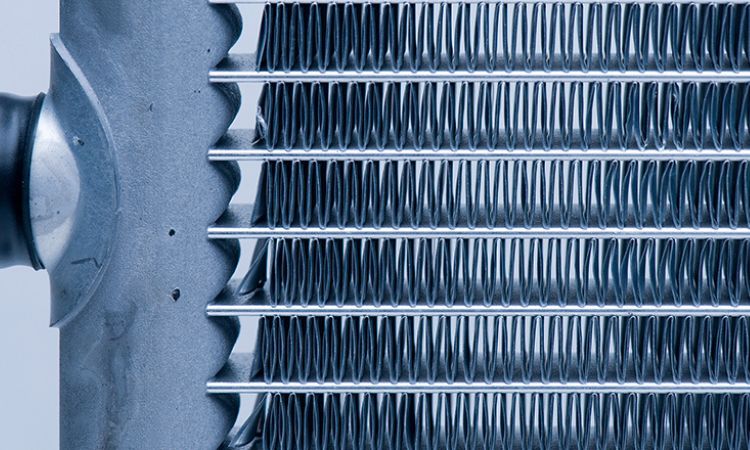

Microchannel heat exchangers are compact, highly efficient devices used to transfer heat between fluids. They feature multiple small channels through which fluids flow, maximizing surface area and enhancing heat transfer efficiency. These heat exchangers offer a wide range of benefits, including reduced weight, smaller size, and superior heat transfer capabilities, making them ideal for applications in sectors like automotive, HVAC, and refrigeration.

The increasing demand for energy-efficient cooling and heating systems is driving the growth of the market. With global efforts to reduce energy consumption and carbon emissions, microchannel heat exchangers are emerging as a solution that can meet these sustainability goals while improving system performance.

Market Segmentation

By Type

Microchannel heat exchangers come in various types, each designed for specific applications. The primary types are condensers, evaporators, and water coils.

Condenser

Microchannel condensers are widely used in automotive, HVAC, and refrigeration systems. These condensers are designed to maximize heat exchange efficiency while minimizing weight and size. The automotive industry’s increasing demand for lightweight and compact cooling solutions is one of the key factors driving the adoption of microchannel condensers. Moreover, the need for better thermal management in electric vehicles (EVs) and hybrid electric vehicles (HEVs) is further contributing to the growth of this segment.

Evaporator

Microchannel evaporators are utilized in various cooling applications, including refrigeration and HVAC systems. These heat exchangers are responsible for absorbing heat from the environment and converting it into a gas. As demand for energy-efficient cooling solutions increases in residential, commercial, and industrial settings, microchannel evaporators are becoming a popular choice due to their compact size and excellent performance.

Water Coil

Water coil microchannel heat exchangers are mainly used in industrial applications, such as HVAC and cooling towers. They are also employed in various processes where water needs to be cooled or heated efficiently. These heat exchangers provide excellent performance in environments where space is limited and efficiency is crucial. The growing demand for cooling systems in industrial processes is expected to contribute to the expansion of this segment.

By Application

Microchannel heat exchangers are used in a wide range of industries, with significant demand arising from the automotive, HVAC, and commercial refrigeration sectors.

Automotive

The automotive industry is one of the largest consumers of microchannel heat exchangers, particularly in air conditioning and cooling systems. The increasing production of electric and hybrid electric vehicles, which require more efficient thermal management systems, is driving the growth of microchannel heat exchangers in this sector. Additionally, the shift towards smaller, lighter, and more energy-efficient vehicles further boosts the adoption of microchannel heat exchangers. These heat exchangers offer several advantages, such as reduced weight, compact design, and higher performance, making them ideal for modern automotive applications.

HVAC

The HVAC (heating, ventilation, and air conditioning) industry is another key application area for microchannel heat exchangers. These heat exchangers are used in both residential and commercial cooling and heating systems, providing high-efficiency solutions for temperature regulation. As demand for energy-efficient and environmentally friendly HVAC systems increases, the microchannel heat exchanger market is poised to benefit. With advancements in HVAC technologies and an increasing focus on sustainability, microchannel heat exchangers are becoming a preferred choice for system designers.

Commercial Refrigeration

Microchannel heat exchangers are also widely used in commercial refrigeration systems, including those found in supermarkets, food storage facilities, and warehouses. These systems require highly efficient heat exchangers to maintain optimal temperature control and ensure energy savings. The growing need for energy-efficient refrigeration systems in commercial settings, coupled with the increasing demand for cold storage solutions, is driving the adoption of microchannel heat exchangers in this sector.

Other Applications

Beyond the primary applications mentioned above, microchannel heat exchangers are increasingly being used in various niche applications, such as power generation, renewable energy, and industrial cooling. These sectors are benefiting from the increased thermal management efficiency that microchannel heat exchangers provide, allowing for improved performance and reduced energy consumption.

Regional Analysis

North America

The North American market for microchannel heat exchangers is witnessing substantial growth, primarily driven by the automotive and HVAC sectors. The United States, in particular, is experiencing a surge in demand for electric vehicles (EVs) and hybrid electric vehicles (HEVs), which require advanced thermal management systems. The region’s focus on sustainability and energy efficiency, along with the adoption of environmentally friendly policies, is further supporting the growth of microchannel heat exchangers. Additionally, the increasing demand for energy-efficient HVAC and refrigeration systems is contributing to the market’s expansion.

Europe

Europe is another key region for the microchannel heat exchanger market, with countries like Germany, France, and the UK being at the forefront of adoption. The automotive industry’s push for lighter, more energy-efficient vehicles, coupled with stringent environmental regulations, is driving the demand for microchannel heat exchangers. Europe is also home to a robust HVAC market, where energy-efficient solutions are in high demand due to rising energy costs and sustainability goals. The region’s focus on innovation and green technologies is expected to continue fueling the growth of the market.

Asia-Pacific

The Asia-Pacific region is expected to experience the highest growth in the microchannel heat exchanger market. The rapid industrialization and urbanization in countries like China, India, and Japan are driving the demand for efficient cooling and heating solutions. The automotive sector in Asia-Pacific, particularly in China, is seeing an increase in the production of electric vehicles, further driving the adoption of microchannel heat exchangers. Additionally, the region’s growing demand for HVAC systems, both residential and commercial, is contributing to the market’s expansion.

Latin America, Middle East, and Africa

The Latin American, Middle Eastern, and African markets are emerging regions for microchannel heat exchangers. Growing industrialization, coupled with the demand for energy-efficient HVAC and refrigeration systems, is driving the market in these areas. The automotive industry’s growth, particularly in countries like Brazil and South Africa, is also expected to boost the demand for microchannel heat exchangers in these regions.

Market Dynamics

SWOT Analysis

Strengths

- Compact size and lightweight design of microchannel heat exchangers make them ideal for applications where space and weight are limited, such as in the automotive industry.

- Superior heat transfer efficiency and energy-saving potential enhance the appeal of microchannel heat exchangers across various industries.

Weaknesses

- High initial cost compared to traditional heat exchangers may deter some industries from adopting these systems, especially in price-sensitive markets.

- The complexity of manufacturing microchannel heat exchangers could lead to challenges in scaling production.

Opportunities

- The rise of electric and hybrid electric vehicles provides a significant opportunity for microchannel heat exchangers to play a vital role in automotive thermal management.

- Increasing demand for energy-efficient HVAC and refrigeration systems in residential, commercial, and industrial sectors is expected to fuel market growth.

Threats

- Competition from traditional heat exchangers and other emerging cooling technologies could pose a threat to the market’s growth.

- Economic downturns or disruptions in global supply chains could impact the availability and cost of raw materials required for microchannel heat exchangers.

Porter’s Five Forces Analysis

- Threat of New Entrants: Moderate. The high capital investment and technical expertise required to manufacture microchannel heat exchangers create barriers to entry, but ongoing innovation may lower these barriers in the future.

- Bargaining Power of Suppliers: Moderate. Raw materials like aluminum and copper are essential for manufacturing microchannel heat exchangers, giving suppliers some bargaining power.

- Bargaining Power of Buyers: Moderate. While buyers demand high-quality and cost-effective products, the specialized nature of microchannel heat exchangers limits their options.

- Threat of Substitutes: Low. Microchannel heat exchangers offer significant advantages in terms of efficiency, compactness, and weight reduction, making them difficult to substitute with other cooling technologies.

- Industry Rivalry: High. The market is highly competitive, with numerous players innovating in product design and manufacturing processes to meet the growing demand for energy-efficient heat exchangers.

Competitive Landscape

The microchannel heat exchanger market is highly competitive, with several established players dominating the market. Companies such as Modine Manufacturing, Danfoss, and ALCO are key players in the market. These companies focus on innovation, expanding their product portfolios, and improving manufacturing processes to meet the increasing demand for energy-efficient and compact thermal management solutions.