Introduction

Checkered plates are versatile materials widely used across industries for their strength, durability, and aesthetic appeal. These plates are easily recognizable due to their unique raised patterns, offering a non-slip surface and added grip.

In this blog, we’ll explore the types, features, and applications of checkered plates, making it easier to understand their importance in various industries.

What Are Checkered Plates?

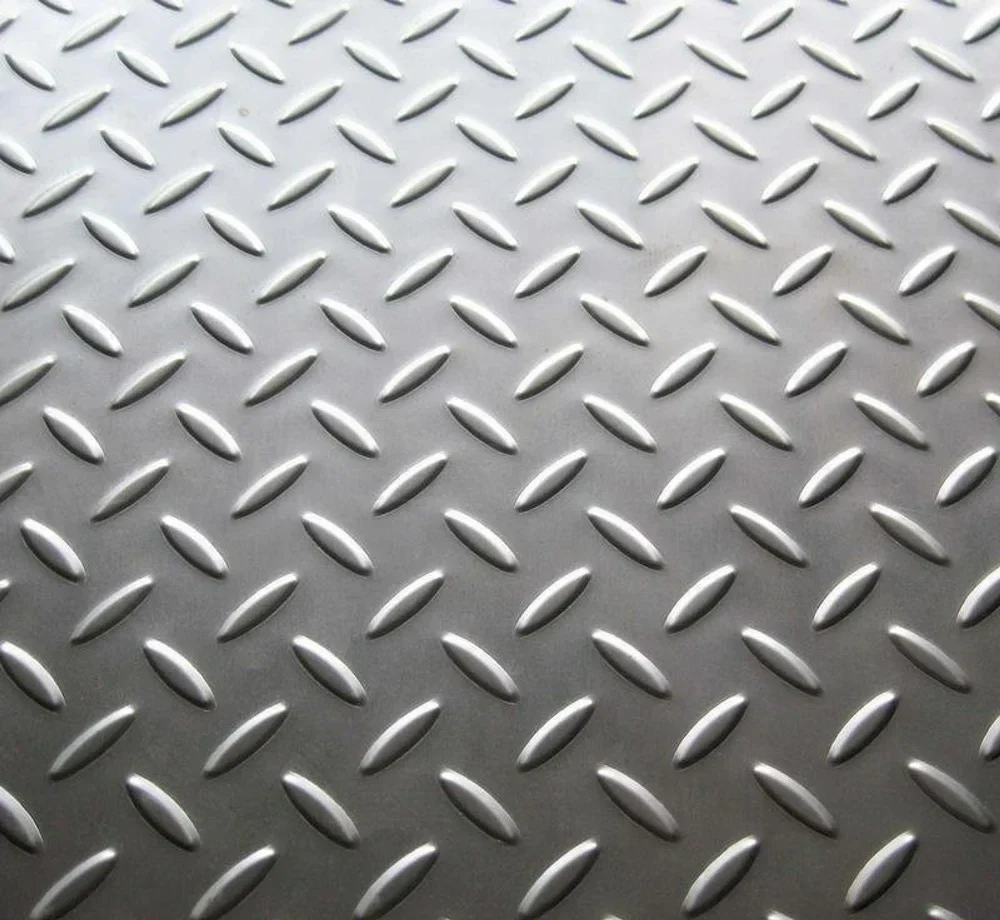

Checkered plates, also known as tread plates or diamond plates, are metal sheets with raised patterns on one side. The textured surface enhances grip and prevents slipping, making them suitable for floors, stairs, and ramps.

These plates are typically made from metals like steel, aluminum, or stainless steel, each offering specific advantages depending on the application.

Types of Checkered Plates

- Steel Checkered Plates

- Known for their strength and durability.

- Commonly used in heavy-duty applications like industrial floors and transportation.

- Aluminum Checkered Plates

- Lightweight and corrosion-resistant.

- Ideal for decorative purposes and in environments exposed to moisture.

- Stainless Steel Checkered Plates

- Combines aesthetics with high corrosion resistance.

- Used in food processing plants and architectural projects.

Key Benefits of Checkered Plates

- Slip Resistance: The raised patterns enhance grip, reducing accidents.

- Durability: Built to withstand heavy loads and harsh conditions.

- Low Maintenance: Easy to clean and maintain, even in demanding environments.

- Aesthetic Appeal: Adds a modern, industrial look to structures.

Applications of Checkered Plates

Checkered plates are used in various sectors, including:

- Construction: As flooring and wall panels in industrial buildings.

- Transportation: For vehicle flooring, truck beds, and trailers.

- Architecture: For decorative purposes in modern interiors and exteriors.

- Marine Industry: Due to their resistance to corrosion in wet environments.

How to Choose the Right Checkered Plate

When selecting a checkered plate, consider:

- Material: Choose steel for strength, aluminum for lightweight needs, and stainless steel for corrosion resistance.

- Thickness: Thicker plates are better for heavy-duty applications.

- Pattern: Ensure the pattern meets your anti-slip requirements.

Checkered plates are not just functional; they are a key component in ensuring safety and reliability in various industries. Their unique design and material properties make them a preferred choice for heavy-duty and aesthetic applications alike.

In this blog, we’ll highlight the advantages and common uses of checkered plates, showcasing their importance in everyday life.

What Makes Checkered Plates Unique?

The raised patterns on checkered plates set them apart from plain metal sheets. This feature adds grip and provides a stylish, industrial look. The material options—steel, aluminum, and stainless steel—make these plates adaptable to different environments.

Top Advantages of Checkered Plates

- Enhanced Safety

- The anti-slip surface minimizes accidents, especially in high-traffic areas.

- Durability

- These plates are built to withstand wear and tear, even in challenging conditions.

- Weather Resistance

- Aluminum and stainless steel plates resist corrosion, making them suitable for outdoor use.

- Cost-Effective

- Their long lifespan reduces replacement and maintenance costs.

- Aesthetic Value

- Adds a polished, professional look to industrial and architectural projects.

Common Uses of Checkered Plates

- Industrial Flooring

- Checkered plates are widely used in factories and warehouses for slip-resistant flooring.

- Transportation

- Found in truck beds, trailer flooring, and ramps for added durability and safety.

- Staircases and Walkways

- The anti-slip surface is ideal for stairs and pedestrian walkways.

- Decorative Purposes

- Often used in furniture design and interior décor for a modern, rugged appearance.

- Marine Applications

- Preferred in ships and docks due to their corrosion resistance.

Tips for Maintaining Checkered Plates

- Regular Cleaning: Use mild detergents to prevent buildup of dirt and grime.

- Inspection: Periodically check for any signs of wear or corrosion.

- Proper Installation: Ensure they are securely fastened to avoid movement and damage.

Environmental Benefits

Many checkered plates are recyclable, making them an eco-friendly choice. Aluminum plates, in particular, are sustainable and widely reused in various industries.

Checkered plates offer unparalleled advantages, from safety and durability to cost-effectiveness and versatility. Whether you’re looking for a practical solution or a decorative element, these plates are an excellent choice.

Conclusion

Checkered plates are an essential material in industries that prioritize safety, durability, and aesthetics. By understanding their features and applications, you can choose the right plate for your project needs.